a visit to nike’s global campus in oregon

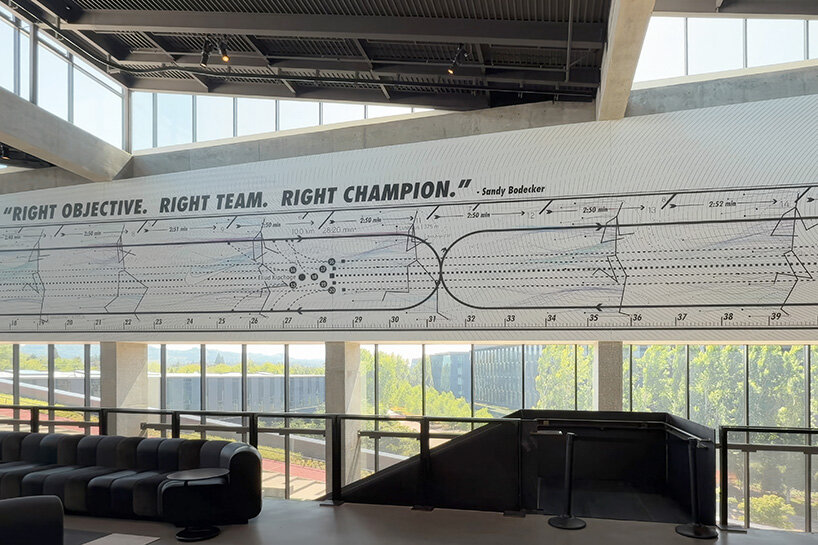

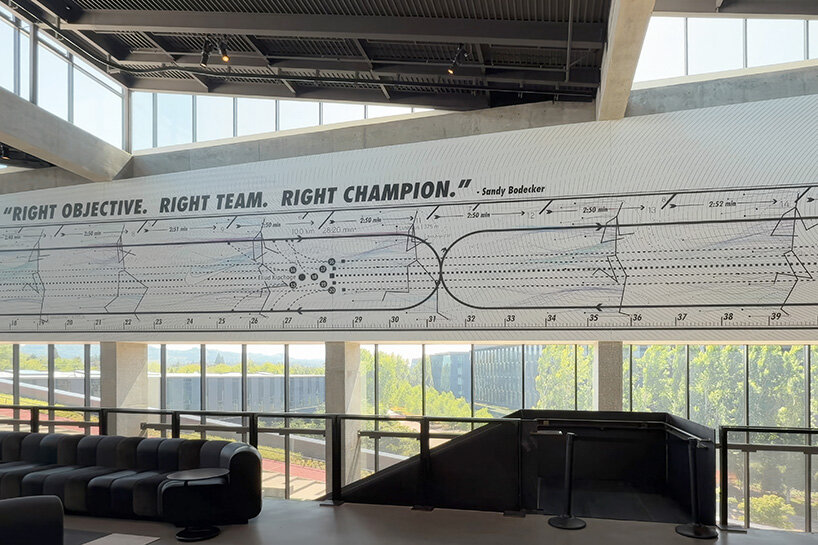

At NIKE’s World Headquarters outside Portland, Oregon, the LeBron James Innovation Center houses the company’s Sport Research Lab, one of its most advanced design environments. This month, designboom visited the state-of-the-art space to preview the Breaking4 Speed Kit being developed for Faith Kipyegon, the three-time Olympic champion who will attempt to become the first woman to run a sub-four-minute mile. The challenge, titled Breaking4: Faith Kipyegon vs. the 4-Minute Mile, represents a collaboration between the athlete and a cross-functional design team whose focus spans footwear, apparel, and performance research.

The lab occupies the fourth floor of the Olson Kundig Architects-designed building, where physical and cognitive testing converge. Motion capture cameras, treadmills outfitted with sensors, and climate-controlled chambers allow NIKE’s teams to simulate race-day conditions. The goal is to understand how the body performs under pressure, and how design interventions can help optimize that performance.

Faith will make the attempt on June 26th, 2025 at Stade Charléty in Paris. NIKE will invite supporters across the world to tune in to a livestream broadcast, which can be viewed here!

the Olson Kundig-designed LeBron James Innovation Center at NIKE World HQ | image © designboom

the NIKE design team collaborates with faith kipyegon

For Brett Kirby, who leads performance research within the Advanced Innovation team at NIKE, the process of designing the Breaking4 Speed Kit begins before the first sketch or sample. His role is to define the structure of the challenge itself. ‘We are aiming toward the mile in four minutes,’ he explains during our visit to the lab. ‘What are the elements that we could start to think about? What’s the homework we need to do to understand this problem?‘

Kirby’s team gathers information not just through data collection but through close listening. His approach involves watching how athletes move, how they adjust their gear without thinking, and what sensory conditions help them settle into focus. ‘We want to take that and create a good observational portfolio of how they are communicating in all ways,’ he says. This kind of introspective, adaptive, and responsive design research sets the foundation for the physical pieces that follow.

inside the NIKE Sport Research Lab | image © designboom

the aerodynamic ‘system of speed’

Once the team’s goal has been structured, NIKE’s footwear and apparel teams begin develop possible solutions. For Faith Kipyegon’s attempt at the sub-four minute mile, those solutions took form as a fully customized NIKE Victory Elite FK spike, a performance FlyWeb Bra, and the aerodynamically tuned NIKE Fly Suit, each built with attention to functionality and sensory experience together.

Lisa Gibson oversees apparel development at NIKE, and described the suit as one of the most aerodynamic systems the brand has created. ‘We learned that Faith wanted to feel like she was running free,’ Gibson emphasizes. That simple idea, freedom of movement, became a central design thread. From there her team sourced materials that were both slick and elastic, then developed construction techniques that placed seams away from the front of the body to reduce drag. Every detail was calibrated through a combination of physical modeling, wind tunnel testing, and environmental simulations.

Integrated into the suit are textured surfaces known as Aeronodes. These small, raised geometries are tuned to generate controlled turbulence, helping the air stay closer to the body and minimizing the wake behind the runner. ‘By creating this controlled turbulence ahead of where larger turbulence would normally occur,‘ Gibson continues, ‘you end up having a smoother flow downstream.’ The result is reduced aerodynamic drag without the need to alter the runner’s natural form.

a running track threads through the colossal interior | image © designboom

a bespoke spike built from the ground up

Footwear innovation for the project is led by Carrie Dimoff, whose team approached the design of Faith’s Victory Elite FK spike as a ground-up reconstruction. Rather than modifying an existing shoe, they began by reviewing the demands of middle-distance racing and drawing insights from Nike’s experience with both marathon and sprint events. ‘We opened the aperture and looked at a lot of different ingredients,’ Dimoff tells us. ‘Then we thought about, ultimately, what’s the best in terms of weight reduction and performance return.’

The final spike includes a Flyknit upper constructed from precision-engineered yarns that deliver strength with minimal weight. Dimoff noted that one component of the upper weighs just three grams. Underfoot, a newly designed Air Zoom unit stores and returns energy, supported by a reengineered carbon plate embedded with six 3D-printed titanium pins for traction. Prototypes were assembled and revised on-site at the LeBron James Building in Oregon, allowing the team to respond to feedback from Kipyegon in real time.

testing chambers measure sweat, body temperatures, and wind | image © designboom

Throughout the process, Kipyegon remained central to every decision. The design team traveled to Kenya to observe her training firsthand and make in-the-moment adjustments. Lisa Gibson recalled watching for what she called ‘unconscious feedback’ — the way an athlete might subtly adjust a seam or pull at a strap. ‘If Faith is tugging on the leg or adjusting the shoulder, that’s telling us something,’ she explains. ‘We dive into that and figure out what’s going on.’

Carrie Dimoff echoes this attentiveness. There were instances, she said, when internal lab data showed no significant difference between two prototypes, but Kipyegon could feel one worked better for her. ‘She is so attuned to her body as a system,” Dimoff said. “If it meant she could run more confidently in it, that was equally as important to us.’

Carrie Dimoff shows Faith Kipyegon’s Breaking4 spike | image © designboom

While the gear developed for Faith Kipyegon’s Breaking4 attempt is entirely bespoke, the innovations produced through the project are already being evaluated for broader application. Elements such as the taller Air Zoom unit, 3D-printed pin systems, and even the textile learnings from the bra design are under review for integration into future footwear and apparel lines. ‘There were lots of things left on the table that didn’t make it into this spike,’ says Dimoff. ‘But we’re really fascinated to dig into them.’

What emerges from Nike’s collaboration with Kipyegon is at once a portrait of a singular athlete at the edge of possibility, and a case study in how design can be shaped by data, environment, sensation, and trust. The effort unfolds through textile calibration, surface tuning, and structured observation. In the end, the system is built from listening and innovation together.